|

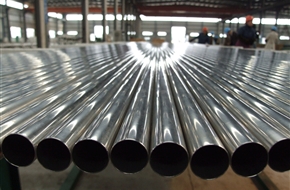

Standard: ASTM A269/ASME SA269 Material: 304, 304L, 316, 316L, 321, 347 Size: OD(16-159mm) x WT (1.5-13mm) Application: Boiler, heat Exchanger, etc. Inspection items: Chemical Composition;Size;Flaring test(seamless);flanging test(welded);Bending test;Hydrostatic Test or Eddy current test or Ultrasonic test;Surface quality;Hardness Negotiated items: Intercrystalline corrosion test;Stabilization heat treatment;BKS tube;Air pressure test under water. |

Chemical Composition

|

Material |

ASTM A269 Chemical Composition % Max |

||||||||||

|

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

NB |

Nb |

Ti |

|

|

TP304 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

18.0-20.0 |

8.0-11.0 |

… |

… |

…. |

… |

|

TP |

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

18.0-20.0 |

8.0-12.0 |

… |

… |

… |

… |

|

TP316 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

16.0-18.0 |

10.0-14.0 |

2.00-3.00 |

… |

… |

… |

|

TP |

0.035 D |

2.00 |

0.045 |

0.030 |

1.00 |

16.0-18.0 |

10.0-15.0 |

2.00-3.00 |

… |

… |

… |

|

TP321 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

17.0-19.0 |

9.0-12.0 |

… |

… |

… |

|

|

TP347 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

17.0-19.0 |

9.0-12.0 |

|

|

|

… |

Mechanical properties

|

Material |

Heat treatment |

Temperure F(C) Min. |

Hardness |

|

|

Brinell |

Rockwell |

|||

|

TP304 |

Solution |

1900 (1040) |

192HBW/200HV |

90HRB |

|

TP |

Solution |

1900 (1040) |

192HBW/200HV |

90HRB |

|

TP316 |

Solution |

1900(1040) |

192HBW/200HV |

90HRB |

|

TP |

Solution |

1900(1040) |

192HBW/200HV |

90HRB |

|

TP321 |

Solution |

1900(1040)F |

192HBW/200HV |

90HRB |

|

TP347 |

Solution |

1900(1040) |

192HBW/200HV |

90HRB |

Size Tolerance

|

OD, inch |

OD Tolerance inch(mm) |

WT Tolerance % |

Length Tolernace inch(mm) |

|

|

+ |

- |

|||

|

≤1/2 |

±0.005(0.13) |

±15 |

1/8(3.2) |

0 |

|

>1/2~11/2 |

±0.005(0.13) |

±10 |

1/8(3.2) |

0 |

|

>11/2~<31/2 |

±0.010(0.25) |

±10 |

3/16(4.8) |

0 |

|

>31/2~<51/2 |

±0.015(0.38) |

±10 |

3/16(4.8) |

0 |

|

>51/2~<8 |

±0.030(0.76) |

±10 |

3/16(4.8) |

0 |

|

8~<12 |

±0.040(1.01) |

±10 |

3/16(4.8) |

0 |

|

12~<14 |

±0.050(1.26) |

±10 |

3/16(4.8) |

0 |